Charmhigh CHMT48VB Pick and Place machine

Download Charmhigh Automatic Chip Mounter(CHM-T48VB) Operating Manual - PDF

Building electronics with a pick and place system

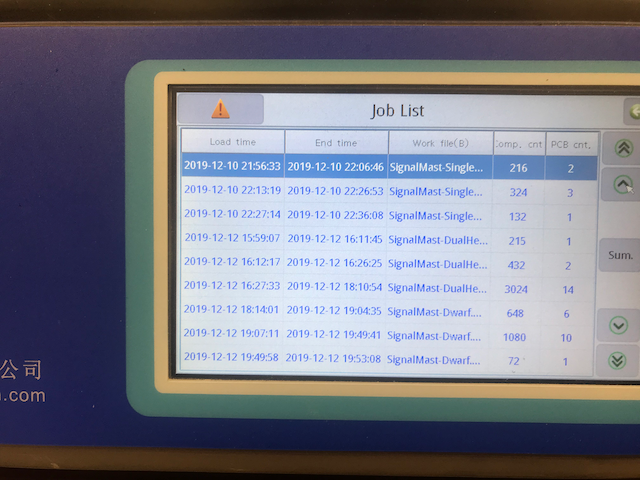

After almost 2 years and several hundred production runs, I've outgrown my CHM-T48VB.It runs reliably at 1500-3000 cph, placing 0805's and SOTs without any issues, and 0602s with a bit of feeder/nozzle calibration tweaking. The only downside (for me) is that component mixes with the drag feeders are time-consuming to change over, so I'm upgrading to a system with interchangeable feeders.

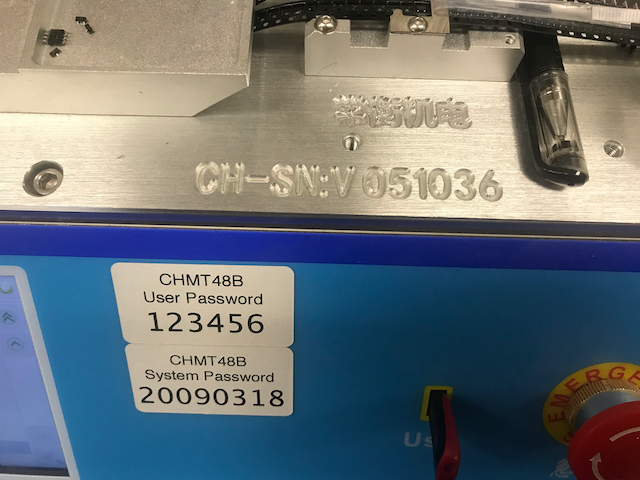

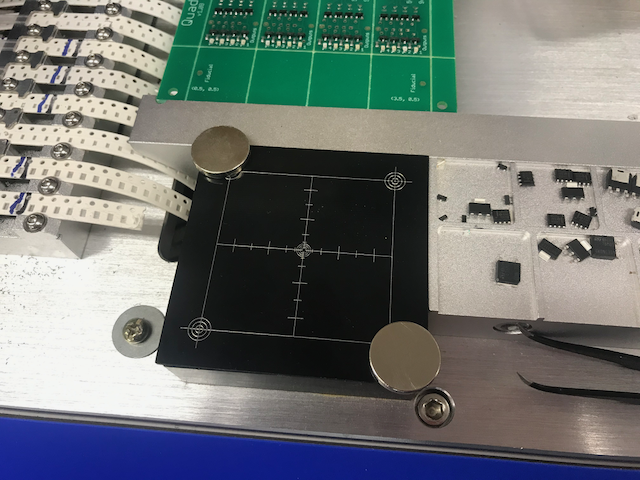

The CHM-T48VB has an embedded Linux controller that loads and runs jobs, it can't be connected to an external PC like the CHM-T36; job transfer is via USB stick using the built in touch screen (I use a SparkFun-derived EagleToCharmHigh program to generate the job files). It has 29 drag feeders each on the left and right, loose part trays for ICs along the front and the ability to pick components out of user-supplied trays within the work area. The system comes with an add-on CharmHigh vibration feeder that mounts to the front-left of the machine for components that come in tubes instead of reels.

Here are some teaching videos from Kimi @ Charmhigh for reference:

- How to creat new file manually in machine directly - Video 1

- How to creat new file manually in machine directly - Video 2

- File convert - from CSV to DPV file:

- Convert and Load in work file:

- How to set Single Pull Needle Position:

- placement offset - Check two places :

- How to install vibration feeder:

- How to Panel / Batch:

- Batch 1 - Array

- Batch 2 - coordinate